Repair of Expansion Joints of a Bridge in Shanghai

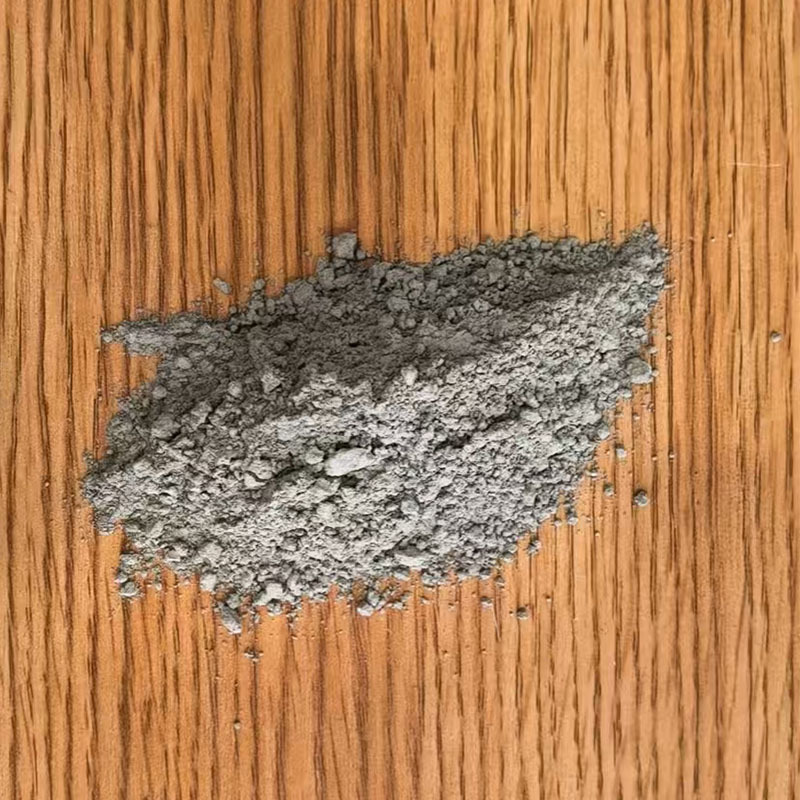

Ultra-Rapid Hardening Cement

Category:

Product Introduction

Product Details

Brief Introduction to Junchiwang

Junchiwang is an epoch-making ultra-rapid hardening cement. Based on Portland cement, it is properly added with finely powdered calcium sulfoaluminate (CSA) component. While maintaining an appropriate hardening time, it exhibits surprisingly high early strength.

Introduction to Junchiwang

Junchiwang is an epoch-making ultra-rapid hardening cement developed through years of research on Portland cement and cement admixtures. Based on Portland cement, it is properly added with finely powdered calcium sulfoaluminate (CSA) component. While maintaining a moderate hardening time, it demonstrates surprisingly high early strength. The compressive strength of concrete can reach over 30MPa within 2-3 hours after pouring, making it the most suitable rapid-setting cement for various emergency projects.

Product Characteristics

1.Practical strength (20-30MPa) can be achieved within 2-3 hours.

2.Similar to Portland cement, it shows stable long-term strength growth. Even at relatively low temperatures, it can develop practical strength in a short time.

3.Small slump loss and excellent workability. Compared with previous ultra-rapid hardening cements, it has smaller slump loss, making construction easier.

4.Enhanced crack resistance. Unlike previous ultra-rapid hardening cements that usually had cracking issues during construction, this product eliminates such troubles.

5.No bleeding and low shrinkage after hardening, ensuring excellent bonding performance with steel bars and good adhesion to old concrete.

6.By adding a retarder on-site, it can better adapt to construction under different environmental conditions.

Product Applications

1.Used in emergency repair projects of highways, railways, bridges, harbors, airports, etc. (e.g., repair of bridge expansion joints, road surfaces, bridge deck pavements, etc.).

2.All concrete construction projects in winter.

Standard Mix Proportion

| Maximum Aggregate Size (mm) | Target Slump (cm) | W/C (%) | s/a (%) | Unit Dosage (kg/m³) | Unit Dosage (kg/m³) | Unit Dosage (kg/m³) | Unit Dosage (kg/m³) |

| Water | Junchiwang | Sand*1 | Aggregate | ||||

| 25 | 8±2.5 | 32 | 40 | 144 | 450 | 712 | 1084 |

*1 Surface Water Adjustment: Adjust the water amount according to the moisture content of aggregates.

*2 The dosage of retarder D500 is adjusted according to the temperature and working time, and it should be dissolved in water before adding (0~0.3% of the cement mass).

Physical Properties

| Temperature (℃) | Slump (cm) | Workable Time (min) | Compressive Strength (MPa) | Compressive Strength (MPa) | Compressive Strength (MPa) | Compressive Strength (MPa) |

| 3 Hours | 1 Day | 7 Days | 28 Days | |||

| 20 | 7.0 | 28 | 32.8 | 44.1 | 57.2 | 63.6 |

| 10 | 7.5 | 41 | 30.2 | 42.7 | 56.5 | 61.1 |

Construction Manual

Ⅰ. Mixing

For mixing ultra-rapid hardening concrete or mortar, follow the steps below:

① First, mix the aggregates with 90% of the water, then add the ultra-rapid hardening cement. (Do not let the aggregates and ultra-rapid hardening cement idle without water.)

② After mixing, the mixture will gradually soften; adjust the slump with the remaining water at the later stage of mixing.

Ⅱ. Construction

The workable time of ultra-rapid hardening concrete and mortar is short. Complete the construction as soon as possible after mixing.

Ⅲ. Curing

Since the concrete generates heat during hardening after pouring, cover the surface with a film after hardening to prevent water evaporation and maintain heat in winter. Additionally, do not spray water within 3 hours.

Ⅳ. Storage

Store this product in the same way as ordinary cement. Do not use products that are in damaged bags or have been opened and left unsealed.

Ⅴ. Caution

This product is an alkaline substance. In case it gets into the eyes, rinse thoroughly with plenty of clean water.

Construction Cases

Notes

- The data recorded in this document is based on representative experimental values and actual conditions; the content herein is not intended to be a guarantee document.

- Before use, your company must conduct preliminary tests and be responsible for verifying whether the product meets the intended use and relevant safety requirements.

- When disposing of our company's products or used products as recorded in this document, please do so in accordance with relevant regulations.

- Before use, confirm the detailed usage methods and precautions through technical documents and Product Safety Data Sheet (SDS).

- The content of this document may be revised without prior notice if new knowledge becomes available. We appreciate your understanding.

Keywords:

Ultra-Rapid Hardening Cement

More Products

undefined

Online Message

Leave a message immediately, and we will arrange a specialist to contact you as soon as possible