Sintered magnesia-alumina Spinel

Category:

Product Introduction

Product Details

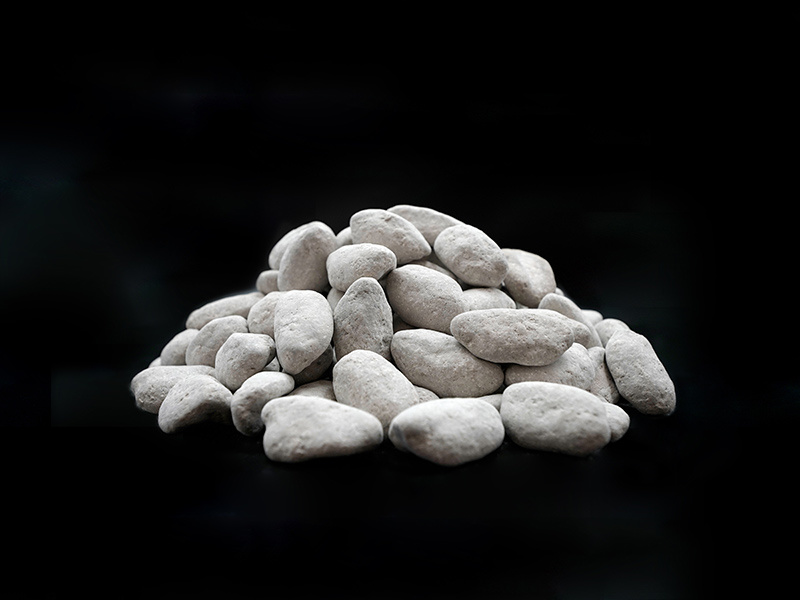

Sintered magnesia-alumina spinel

Brief Introduction

Sintered magnesia-alumina spinel has good crystal development, small grain size, high content of spinel phase, good sintering activity, and good thermal shock stability.

Introduction

‘Jun’ brand sintered magnesia-alumina spinel is made from industrial alumina and calcined magnesia as raw materials, and is sintered in an ultra-high temperature shaft kiln through a multi-stage homogenization process. It has a high bulk density, well-developed crystals, small grain size, high content of spinel phase, good sintering activity, and uniform structure. magnesia-alumina spinel has superior characteristics such as corrosion resistance, anti peeling, good slag resistance, good thermal shock stability, and high temperature resistance.

High quality sintered magnesia-alumina spinel provides a guarantee for the production of unshaped and shaped high-performance refractory materials. It is an ideal raw material for refractory products such as magnesia-alumina spinel bricks for cement rotary kilns, ladle lining bricks, and ladle castables. It is widely used in steel metallurgy, cement rotary kilns, and glass industry kilns. According to the alumina content, sintered magnesia-alumina spinel is divided into SAM-50, SAM-66, SAM-78, and SAM-90.

Physical and chemical parameter

| Al₂O₃ | MgO | CaO | SiO₂ | Fe₂O₃ |

Na₂O |

Bulk Density(g/cm³) |

|

|

SAM-50 |

48~52 |

46~50 |

≤0.60 |

≤0.45 |

≤0.35 |

≤0.25 |

≥3.2 |

|

SAM-66 |

64~68 |

32~36 |

≤0.50 |

≤0.35 |

≤0.30 |

≤0.30 |

≥3.2 |

|

SAM-78 |

76~79 |

20~24 |

≤0.40 |

≤0.30 |

≤0.25 |

≤0.35 |

≥3.2 |

|

SAM-90 |

89~92 |

8~11 |

≤0.30 |

≤0.25 |

≤0.20 |

≤0.35 |

≥3.3 |

|

Sizes |

0~0.2~0.5~1~2~3~5~8mm,100mesh、200mesh、325mesh,5μm,3μm。 | ||||||

|

inspection standard |

GB5069-2001 | ||||||

|

Packing |

25KG/small bag,1000KG/jumbo bag(can be customized according to customer requirements) |

||||||

Keywords:

Sintered Magnesium Aluminum Spinel

Online Message

Leave a message immediately, and we will arrange a specialist to contact you as soon as possible