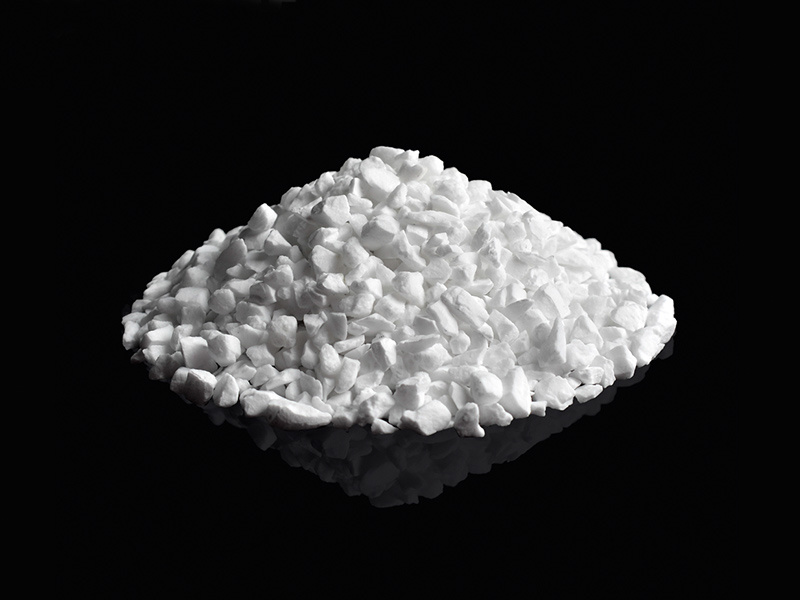

Reactive Alumina Powder

Product Introduction

Product Details

Product Introduction

The reactive alumina powder produced by our company features low impurity content, controllable sintering activity, small primary grain size, and high α-phase conversion rate. It serves as a crucial raw material for manufacturing high-quality refractory materials.

Product Introduction

Our AW series of reactive α-Al₂O₃ micropowder is manufactured to corporate standards exceeding those of renowned international alumina micropowder producers. Utilizing a unique production process, the product achieves low impurity content, controllable sintering activity, fine grain size, and high phase transformation rate, making it a vital raw material for producing high-quality refractory materials.

Our products are selected and utilized by major domestic and international refractory manufacturers and research institutes for producing key items such as ladle castables, iron groove castables, permeable bricks, seat bricks, corundum self-flowing castables, spray coatings, skid plates, magnesia-carbon bricks, and lithium battery crucibles. They are also exported to renowned refractory producers in Japan, the United States, Europe, Russia, and Southeast Asia.

Our AW series α-Al₂O₃ micropowder employs a particle size control model to effectively regulate and optimize particle distribution. Combined with specialized additives for phase transformation and surface modification, this process yields alumina micropowder characterized by low impurity content, fine particle size, and a rational particle size distribution. When used in castables, it exhibits excellent flowability, low expansion, extended working time, high intermediate-temperature strength, dense structure, and excellent performance.

Physical and Chemical Properties of reactive Powder

| Grade | AW-SF | AW-12M | AW-06L | Compound powder | ||||

| Ingredients % | Warranted | Typical | Warranted | Typical | Warranted | Typical | Warranted | Typical |

| AL2O3 | ≥98.50 | 99.08 | ≥99 | 99.50 | ≥99 | 99.60 | ≥99 | 99.51 |

| SiO2 | ≤0.20 | 0.10 | ≤0.20 | 0.12 | ≤0.20 | 0.10 | ≤0.20 | 0.09 |

| Fe2O3 | ≤0.20 | 0.13 | ≤0.20 | 0.08 | ≤0.20 | 0.05 | ≤0.20 | 0.04 |

| Na2O | ≤0.25 | 0.13 | ≤0.20 | 0.18 | ≤0.20 | 0.04 | ≤0.30 | 0.12 |

| Medium particle size D50μm | 2~3 | 2.5 | 1~2 | 1.90 | 0.6~1.5 | 1.4 | 2.5~3.5 | 2.7 |

| Particle Distribution | Bi-modal | Mono-modal | Mono-modal | Multi-modal | ||||

| Inspection Standards | GB/T3044-89;GB3604-83 | |||||||

| Packaging | 25KG/small bag,1000KG/jumbo bag(can be customized according to customer requirements) | |||||||

Note:

Particle size can also be processed according to customer requirements.

For other special performance requirements, please contact us for customized production.

Keywords:

Reactive Alumina Powder

Online Message

Leave a message immediately, and we will arrange a specialist to contact you as soon as possible