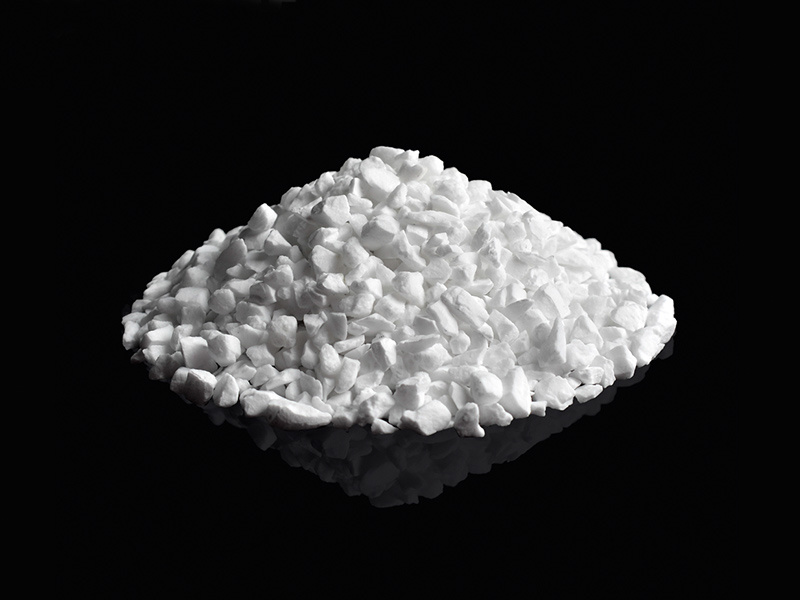

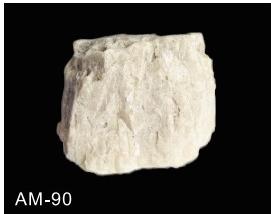

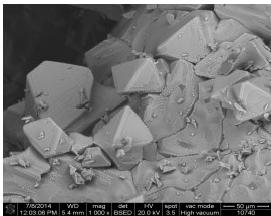

Fused magnesia-alumina spinel AM90

Product Introduction

Product Details

AM-90 Brief Introduction

AM-90 spinel exhibits high density, high refractoriness, high solid solution content, low thermal expansion coefficient, and excellent thermal shock stability.

AM-90 Introduction

"Jun" brand high-purity fused magnesia-alumina spinel is smelted from high-purity magnesium powder and industrial alumina powder in large-scale high-temperature electric arc furnaces. It has characteristics such as high density, high refractoriness, high solid solution content, low thermal expansion coefficient, good high-temperature volume stability, excellent resistance to alkaline slag penetration, and superior thermal shock stability. It is widely used in ladle walls, porous plugs/seat bricks, RH spinel bricks/backing castables, alloy smelting, and lithium battery saggers.

The addition of magnesia-alumina spinel to refractories can notably improve the fluidity, impermeability, erosion resistance, and spalling resistance of castables. Especially, it enhances scouring resistance, prolongs service life, and lowers refractory consumption per ton of steel.

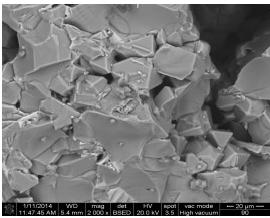

Physical Properties and Chemical Composition

| Composition Item | AL₂O₃ | MgO | CaO | SiO₂ | Fe₂O₃ | Na₂O | Bulk density (g/cm³) |

| AM-65 | 64~66 | 33~35 | ≤0.65 | ≤0.50 | ≤0.40 | ≤0.30 | ≥3.3 |

| AM-75 | 74~76 | 23~25 | ≤0.55 | ≤0.40 | ≤0.40 | ≤0.30 | ≥3.2 |

| AM-90 | 87~90 | 9~12 | ≤0.30 | ≤0.25 | ≤0.30 | ≤0.40 | ≥3.3 |

| Particle size | 0~0.2~0.5~1~2~3~5~8mm,100 mesh、200 mesh、325 mesh、5μm | ||||||

| Inspection standard | GB5069-2001 | ||||||

| Packing | 25KG/small bag,1000KG/jumbo bag(can be customized according to customer requirements) | ||||||

Keywords:

Fused magnesium aluminum spinel AM90

Online Message

Leave a message immediately, and we will arrange a specialist to contact you as soon as possible